Industry BackgroundRequirement Analysis

-

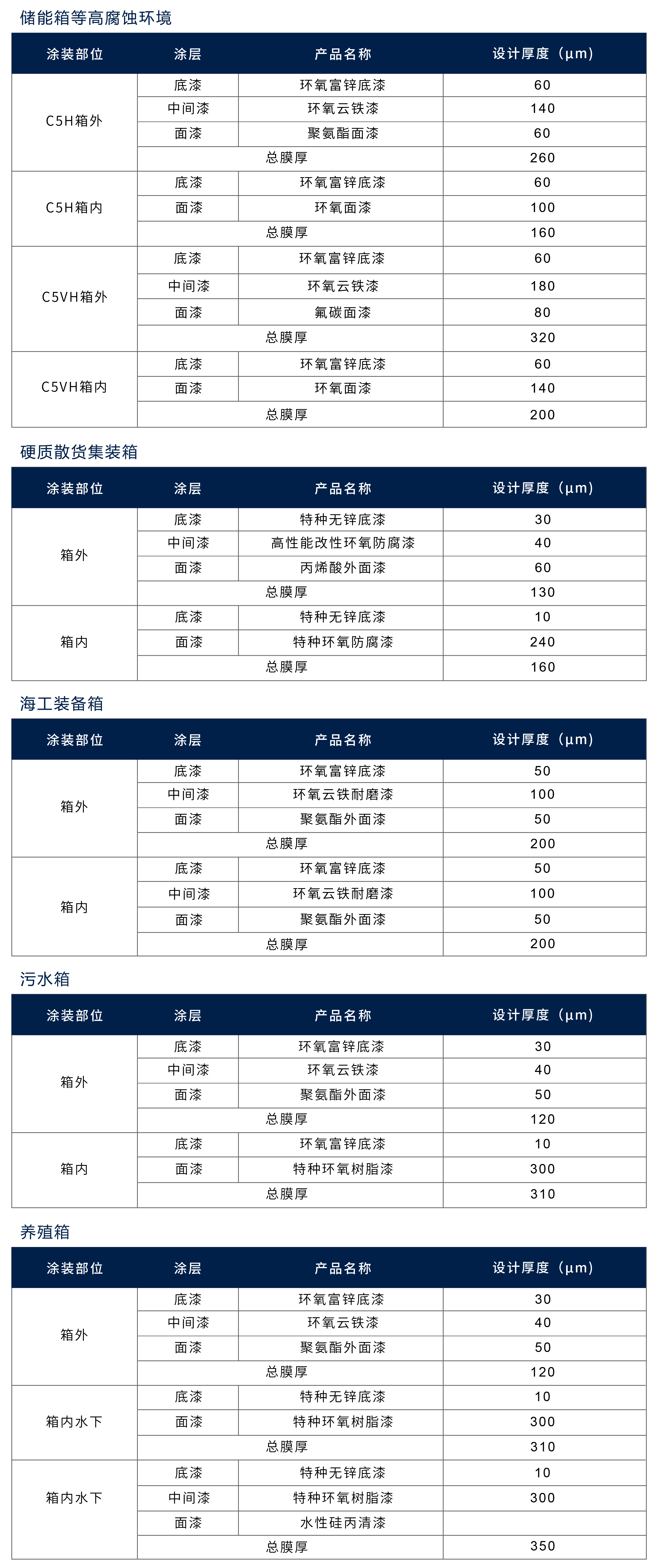

Harsh Operating Environment: including temperature fluctuations, exposure to wind, rain, ultraviolet radiation, atmospheric corrosion, seawater impact, and chemical erosion.

-

High Corrosion Resistance Requirements: As most containers are constructed with steel structures and need to carry various types of cargo, they must possess excellent corrosion resistance to ensure the safety of the cargo and the long-term use of the containers.

-

Diverse Corrosion Protection Solutions: To meet the corrosion protection needs of special containers, materials with good acid and alkali resistance, chemical medium corrosion resistance, and high abrasion resistance are used.

Product ApplicationCore Requirements

-

A rich product line, meets the process coating requirements of the container manufacturing assembly line. The coating process is integrated into every stage of manufacturing, aligning with the production rhythm of the container bodies. It ensures uniform film thickness, excellent coating appearance quality, and the absence of issues such as pinholes, bubbles, and sagging.

-

The excellent anti-corrosion performance ensures that the coating of each part of the box has a high anti-corrosion ability. Good weather resistance, color diversity and high richness to meet the owner's aesthetic decoration needs for the special box.

-

Excellent mechanical properties, shock resistance. Favorable environment with low VOC emissions, excellent coating workability and coating compatibility.

Execute standardfile download

Storage-Container Solution

MoreRecommended products

Collaborate with China Fluoride to promote the industry

MoreRecommended solutions