Industry BackgroundRequirement Analysis

-

The working environment of the equipment is harsh, with high temperature, high pressure, humidity, acidic or alkaline environment, and petrochemical equipment requires a large amount of metal materials to be made, making corrosion problems difficult to avoid.

-

Anti corrosion requirements: weather resistance, water resistance, salt spray resistance, chemical atmosphere resistance, UV resistance, acid rain resistance.

-

Improve the service life of equipment, reduce maintenance and repair costs, and minimize environmental pollution to ensure the sustainable development of the petrochemical industry.

Product ApplicationCore Requirements

-

Ultra-high weather resistance, fluorine resin molecular structure contains fluorine - carbon (F-C) bond energy as high as 485.6KJ/mol, is the strongest known organic chemical bond, much larger than the ultraviolet radiation energy of 411KJ/mol, so the ultraviolet radiation energy is not able to break the connection of the F-C bond, to ensure that the film of ultra-high weather resistance.

-

Superb corrosion and chemical resistance, maximum structural integrity and tightness. Fluorocarbon resin molecular structure provides excellent adhesion, corrosion resistance, high self-cleaning, chemical resistance and stain resistance to the paint film.

-

Execute standardfile download

GB 50393-2008 《钢质石油储罐防腐蚀工程技术规范》 《中国石化工程建设管理标准-炼化企业视觉形象工程规定》 《炼油企业防腐涂层质量控制技术管理要求》

Crude-Oil Storage Tanks Solution

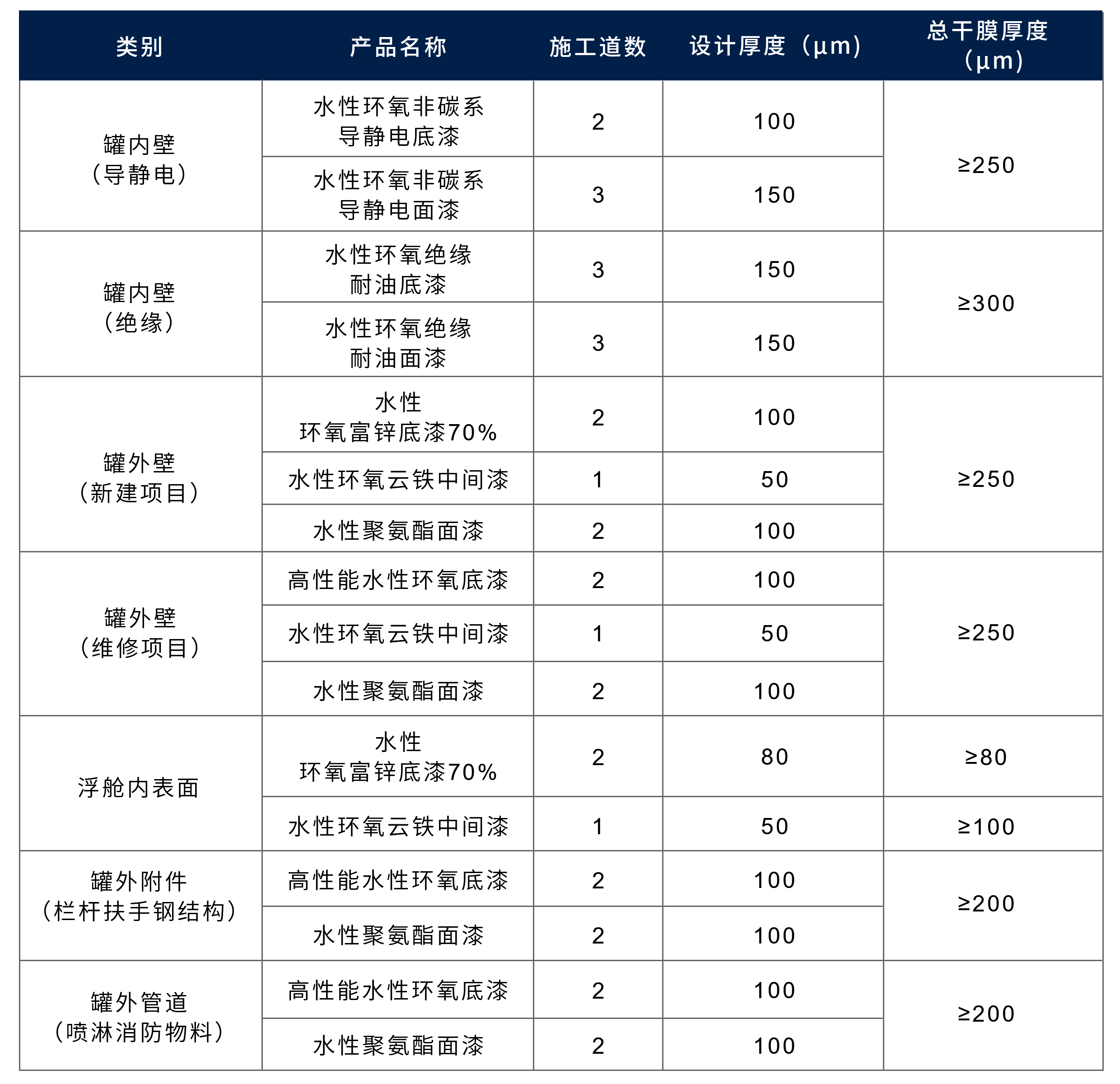

外防腐涂装

防腐部位,浮顶上表面、罐壁外表面、顶圈罐壁内表面 2 米、抗风圈和加强圈上下表面及平台、梯子等钢结构表面等。

内防腐涂装

防腐部位,罐底板上表面和底圈罐壁内表面 1.8 米以下,采用无溶剂环氧环保型耐油绝缘型内防腐涂层与牺牲阳极阴极保护相结合,防腐涂层的表面电阻率不应低于 1×1013Ω。

其他部位涂装

浮顶下表面、浮舱外边缘板外表面、接触介质的浮顶构件,采用无溶剂环氧非碳系列耐油内防腐涂层,防腐涂层的表面电阻率应在 108 ~1011Ω 之间。浮舱内表面、浮舱钢结构等,采用水性环氧绝缘型内防腐涂层。

MoreRecommended products

Collaborate with China Fluoride to promote the industry

MoreRecommended solutions